DOUBLE KNIFE GUILLOTINE TRM-2L

The TRM-2L guillotine, hydraulically driven, allows the simultaneous cutting of two sides of the veneer bundle along the length.

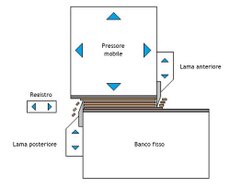

The machine has a robust structure, essential for obtaining a quality cut. The workbench and the rear blade are fixed, the presser and the built-in upper blade are movable. This allows for greater ease of use of the machine by the operator. The rear register, to positioning the veneer bundle, is precise and fast thanks to the sliding on linear guides. The machine is equipped with a touch screen control with customizable programs and laser cutting point indicator.

Furthermore, on request it can be equipped by automatic stacking system for automated lines, balancing system, automatic square for 45° or 90° cutting. The machine is ideal for large productions.

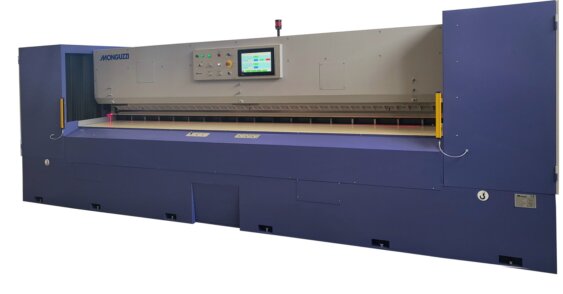

DOUBLE KNIFE GUILLOTINE WITH GLUE UNITS PULCHRA

Video Pulchra

Hydraulically driven two-blade guillotine. This guillotine, unique in the world, allows cutting and applying glue on two sides of the veneer bundle in a single operation. The glue is applied with the veneer bundle completely pressed and stopped. This guarantees a safe and uniform application of the glue over the entire surface of the veneer bundle. The glue units run on latest generation linear magnetic motors. It is possible to dose the quantity of glue to be applied on the veneer bundle. The glue trays are equipped with refrigeration units to prevent the glue from drying out during short break periods. The machine is equipped with color computer.

Upon request, it can be equipped with a milling unit for processing thick veneer. It is ideal for large productions and allows to serve up to 2/3 cross feed splicers.

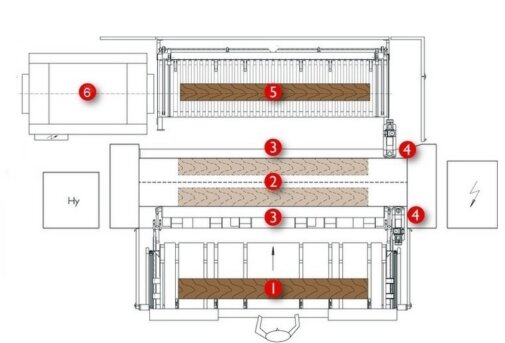

The operator places the veneer bundle on the loading table (1) and, via computer or laser, establishes the cutting points.

The bundle is introduced, automatically, by the loading table clamps, into the machine to be pressed, cut (3) and glued (4) on the first side. The central clamps (2) transport the bundle to the rear part of the machine where it is pressed, cut (3) and glued (4) on the second side.

The bundle is then unloaded automatically by the rear clamps with roller conveyor (5) and generally introduced into the fanning machine. The machine also allows the splitting of the veneer bundle into two parts and double cutting.

Monguzzi & Fisher+Rückle S.r.l.

Contact us

Registered office:

Largo Carlo Esterle n. 1 - 20900 Monza (MB) Italia

Headquarters:

Via Marsala n. 5 - 20061 Carugate (MI) Italia

Tel.: +39 02 9253802

e-mail: info@monguzzi.net